Looking to bring your brand to life in 3D? Whether it’s a retail mascot, a thematic installation, or a large-scale event centerpiece, custom sculptures are powerful tools that transform ideas into unforgettable experiences.

At Corzzair, we specialize in custom sculpture fabrication in Malaysia and Singapore, turning client concepts into captivating, photo-worthy works of art. Here’s a closer look at our complete process—from initial sketch to final installation.

1. Initial Client Consultation and Creative Brief

Every successful custom sculpture starts with a clear conversation. At Corzzair, our fabrication journey begins by understanding your vision, space, and goals. Whether it’s a commercial art installation, retail prop, or public feature, we ask the right questions to define the scope: What’s the purpose of the piece? Where will it be displayed? Do you have a theme or brand identity to express?

During this consultation, we develop a creative brief that outlines key design requirements, dimensions, budget, timeline, and artistic direction. This brief becomes our guiding document throughout the project. We also showcase past works and material options to inspire ideas and align expectations. It’s a true collaboration — one that ensures your custom sculpture is both stunning and strategically designed.

2. Concept Sketching and 3D Design Mockups

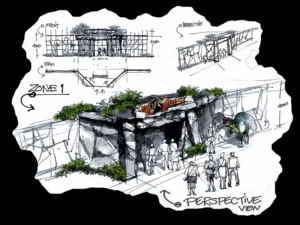

Once the creative brief is finalized, our design team transforms ideas into visual concepts. This begins with hand-drawn sketches that capture the overall shape, style, and presence of the sculpture. These early visuals help both parties align on design intent and creative direction before moving into digital modeling.

We then develop detailed 3D mockups using advanced design software. These renderings allow you to visualize the sculpture from every angle, evaluate scale and proportions, and suggest refinements — all before any material is cut. For event managers and brand marketers, this stage is especially valuable: it provides a realistic preview of how the sculpture will look in context, whether it’s a showstopping centerpiece, photo op, or experiential display.

Feedback loops are built into this phase to ensure the final design is both visually impactful and practical for installation, logistics, and audience engagement.

3. Materials Selection: Foam, Fiberglass, Wood, etc.

Choosing the right materials is key to balancing visual impact, durability, and budget. At Corzzair, we offer a curated range of fabrication materials to suit different environments and creative goals. High-density foam is ideal for lightweight, large-scale builds — perfect for short-term events or indoor installations. Fiberglass offers strength and weather resistance, making it ideal for long-term outdoor displays or public art.

Wood adds warmth and structure, especially in scenic builds or retail environments where a natural aesthetic is preferred. We also advise on finishes — from high-gloss automotive paint to textured coatings — to match branding and lighting conditions.

Our team will guide you through the options to ensure your custom sculpture is not only visually stunning, but also engineered for where and how it will be experienced.

4. Fabrication Process: CNC, Hand Sculpting, Painting

With designs approved and materials selected, we move into full-scale fabrication — the stage where your custom sculpture transitions from concept to reality. At Corzzair, we blend advanced digital fabrication with time-tested craftsmanship to ensure precision and personality in every build.

Our process often starts with CNC machining, which carves out base shapes from foam or wood using computer-guided precision. This is ideal for large-scale pieces that need structural integrity and consistency. From there, our artisans take over with hand sculpting, refining the form, adding texture, and ensuring every detail aligns with the approved mockup.

Once the structure is complete, we apply surface treatments — including coating, sanding, and priming — to prep the sculpture for its final look. The final stage is custom painting, where we match brand colors, create realistic effects, or apply bold artistic finishes. We use everything from matte textures to high-gloss automotive paints, depending on the design goals and lighting conditions.

This hybrid approach ensures your sculpture is both visually compelling and structurally sound — built to impress, whether it’s under stage lights, on a tradeshow floor, or outdoors in the elements.

5. Final Installation and Delivery

Once your sculpture is complete, our team coordinates the final delivery and installation — ensuring a smooth handoff from studio to showtime. Whether it’s a high-traffic event, retail rollout, or outdoor exhibit, we handle logistics with precision and discretion.

We conduct site assessments when needed, plan for access and rigging, and ensure all components arrive safely and on schedule. Our installation crews are trained to work quickly and professionally, minimizing disruption while maximizing impact. From protective packing to final placement, every step is handled with care.

With Corzzair, you’re not just getting a sculpture — you’re getting peace of mind.

Why Work with Corzzair?

- End-to-End Process: Design, fabrication, and installation under one roof

- Proven Track Record: Clients include Resorts World, Nike, Huawei & more

- Based in Johor, Serving Malaysia & Singapore

Ready to Build Something Bold?

Let’s create a custom sculpture that gets your brand noticed.

Contact us today to start your custom fabrication journey.