Exhibitions rely on high-quality props to create immersive experiences that capture attention and engage visitors. Whether for trade shows, museums, brand activations, or themed events, custom exhibition props must be visually striking, durable, and aligned with the event’s theme.

But what goes into creating exhibition props? From concept design to fabrication and installation, this guide walks you through the step-by-step process of making exhibition props.

Key Takeaways

- Exhibition props enhance visual storytelling and brand engagement.

- The process includes concept design, material selection, fabrication, and finishing.

- 3D modeling and prototyping help refine designs before production.

- Foam, fiberglass, wood, and metal are commonly used materials.

- Professional prop-making ensures durability, realism, and functionality.

Step-by-Step Process of Creating Exhibition Props

1. Concept Development & Planning

Before anything is built, the vision and purpose of the exhibition prop must be defined.

Key Steps:

- Understanding the event theme, space, and objectives.

- Sketching initial design concepts.

- Creating a mood board with references.

- Determining size, colors, branding elements, and interactivity.

Example: A car brand at an auto show might need a life-size model of an engine to demonstrate its technology to visitors.

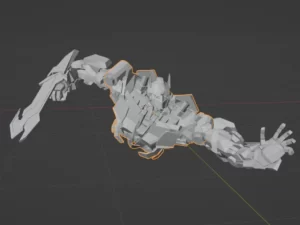

2. 3D Modeling & Prototyping

Before fabrication, a 3D model is created to visualize the prop in a digital space.

Why 3D Modeling Is Important:

- Ensures accuracy and proportions.

- Allows for design refinements before production.

- Helps clients visualize the final prop in the exhibition space.

Example: Theme parks use 3D models to design animatronic characters before sculpting them in real life.

3. Choosing the Right Materials

The material selection depends on factors like durability, weight, budget, and aesthetic needs.

| Material | Best For | Pros | Cons |

|---|---|---|---|

| Foam (EPS, XPS, EVA) | Lightweight props | Easy to carve, budget-friendly | Less durable |

| Fiberglass | High-detail, durable props | Strong, weather-resistant | Requires molds |

| Wood (Plywood, MDF) | Structural elements, signage | Sturdy, easily shaped | Heavier than foam |

| Acrylic & Plastics | Transparent, futuristic props | Polished finish, lightweight | Can be fragile |

| Metal (Steel, Aluminum) | Industrial & durable props | Long-lasting, high-end look | Expensive |

Example: A museum exhibition may use fiberglass for dinosaur models and wood for display cases.

4. Fabrication & Sculpting

Once materials are chosen, fabrication begins.

Common Fabrication Techniques:

- 3D Printing: Best for small intricate details.

- CNC Machining: Used for precise wood & metal cuts.

- Foam Carving: Great for large-scale sculptures.

- Molding & Casting: Used for fiberglass props.

- Hand Sculpting & Painting: Adds fine details & textures.

Example: An exhibition booth at a trade show may include custom-carved foam sculptures coated in fiberglass for durability.

5. Painting, Finishing & Branding

The painting and finishing stage brings the prop to life.

Finishing Techniques:

- Airbrushing & Hand-Painting: Adds realistic colors and details.

- Texturing: Creates wood, stone, or metal effects.

- Branding Elements: Logos, decals, and interactive features.

- Protective Coatings: Ensures durability and weather resistance.

Example: A fashion brand’s exhibition might use luxury textures and metallic finishes to create a high-end aesthetic.

6. Installation & On-Site Setup

Once the props are built and painted, they are transported and installed at the exhibition venue.

Installation Considerations:

- Ensuring safe transport with proper packaging.

- Modular assembly for easy setup.

- Securing props firmly in place for stability.

- Testing interactive elements like lights, sounds, or motion.

Example: A science museum exhibit might have a giant model of the solar system suspended from the ceiling, requiring careful rigging and safety measures.

Industries That Use Exhibition Props

Trade Shows & Corporate Events

- Product displays & branded installations

- Interactive customer experiences

Museums & Educational Exhibits

- Life-size historical replicas

- Interactive learning displays

Theme Parks & Entertainment

- Fantasy & sci-fi props

- Animatronics & themed attractions

Retail & Storefront Displays

- Seasonal window displays

- High-impact branding props

How to Choose the Right Prop Maker for Your Exhibition

| Factor | Why It Matters |

|---|---|

| Experience in Exhibition Design | Ensures expert craftsmanship and industry knowledge. |

| Material Expertise | The right maker will recommend the best materials based on your needs. |

| Customization Abilities | Look for companies that offer fully custom fabrication. |

| Previous Work Portfolio | Check past museum, trade show, and brand activation projects. |

| Installation Support | Some prop makers provide on-site setup & maintenance services. |

Need expert-made exhibition props? Work with professionals to create stunning, high-quality displays that leave a lasting impact!

Final Thoughts

Creating exhibition props requires a blend of artistry, engineering, and technical expertise. Whether you’re designing for a trade show, museum, or entertainment event, the right materials and techniques will ensure your props stand out and last long.

- 3D modeling and prototyping help refine designs before production.

- Foam, fiberglass, and metal are top materials for durability and realism.

- Professional fabrication ensures quality, branding, and interactivity.

Need Custom Exhibition Props? Let’s Make Your Vision a Reality!

Transform your event with custom-made exhibition props designed for impact, durability, and engagement.

- High-quality, weather-resistant materials

- Custom branding & interactive features

- Expert craftsmanship for museums, trade shows & events

Get a Free Consultation Today! Contact Us